Featured Article on Intelligent Compaction Technology

16 March 2022(Image source – Infrastructure Magazine March 2021)

NACOE features on front cover of Infrastructure Magazine March 2021 edition for Intelligent Compaction project.

The National Asset Centre of Excellence (NACOE) has been investigating Intelligent Compaction (IC) technology and the role it can play in constructing roads in Queensland. This research focuses on the use of IC to improve the construction quality of both earthwork embankment and pavement construction. Activities have been undertaken to accelerate market acceptance in Australia.

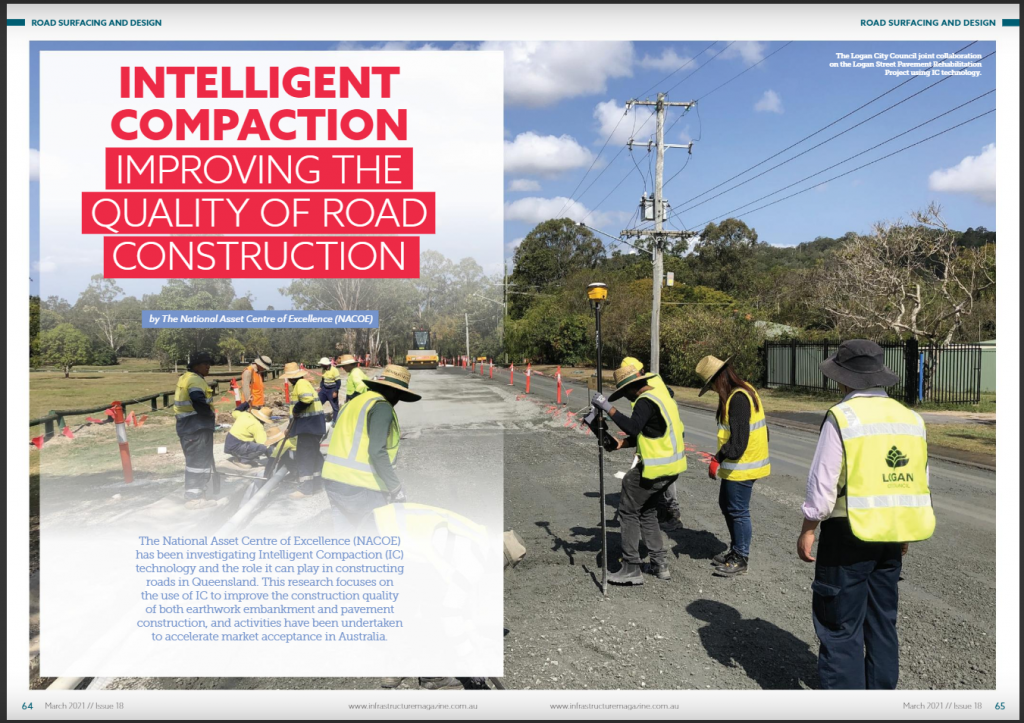

The Logan City Council joint collaboration on the Logan Street Pavement Rehabilitation Project using IC technology.

What role does the quality of compaction in road construction have on delivering a long-lasting, high performing pavement? The industry knows just how vital the compaction process is to achieve the best outcome. Many local and state governments are becoming increasingly concerned with costly repairs and maintenance that can occur later down the road due to poorly compacted pavements.

Intelligent compaction technology has the potential to significantly reduce construction and maintenance costs, by optimizing the compaction process through improved uniformity and consistency of materials. It brings with it real-time feedback and monitors to assist the roller operator, using a system of hardware, software, and analysis equipment.

Although IC technology is quite new to Australia, it has a proven track record overseas, where it was first developed in Europe and has been increasingly used throughout Asia and the United States. As part of the National Asset Centre of Excellence (NACOE) program, a research project commenced in January 2019 intending to assess the suitability of implementing Intelligent Compaction for quality control in future road construction.

What Is Intelligent Compaction Technology?

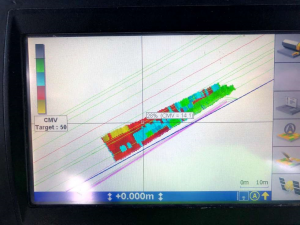

Intelligent compaction (IC) refers to the use of a roller equipped with an integrated measurement system, often using an accelerometer mounted on the roller drum and a precision GPS unit. For the use of asphalt compaction, infrared temperature sensors are also mounted on the roller to track asphalt surface temperature during compaction. The IC technology has an on-board computer display which provides the operator with real-time feedback on the stiffness of the compacted materials and the number of roller passes the roller has made.

IC rollers allow the operator to view plots of the precise location of the roller and continuously determine a measured value of the material stiffness and number of roller passes during the compaction process by maintaining an ongoing record of colour-coded plots.

What are the benefits of using Intelligent Compaction?

Through researching international best practise and field testing the technology in Queensland, Intelligent Compaction is displaying benefits in the following areas:

- Real-time operator feedback enabling continuous placement of material (without delays of traditional test methods)

- Identify weak areas on pre-mapping of underlying layers

- Optimise rolling pattern (coverage and speeds)

- Allows for 100% of compacted area to be assessed, avoiding under/over compaction of isolated areas

- Capturing and securely storing the compaction process information as permanent geo-referenced records

- Improved uniformity of earthworks and pavements, which is expected to lead to significant improvements in service life

- Reduction in greenhouse gas emissions due to more efficient construction practices and reduced maintenance.

First ICDM Workshop in Queensland

Image – First Intelligent Compaction Data Management (ICDM) workshop held in June 2019.

The NACOE research on IC implementation is led by Dr. Jeffrey Lee, who delivered the first-ever two-day Intelligent Compaction Data Management (ICDM) workshop held in Queensland in 2019, alongside Dr. George Chang.

The first day of the event covered the basics of intelligent compaction, which gave participants a hands-on experience of using the Veta software. On the second day, a field demonstration was conducted using a Dynapac smooth drum roller with a Trimble IC retrofit kit at a test strip, where the IC roller was used to compact a general fill area (60 m by 23 m) on test strips using three different moisture contents.

The exercise familiarised participants with IC technology and demonstrated how to use a test strip to establish a target Intelligent Compaction Measurement Value (ICMV) and roller passes for process control.

Development of First Technical Specification for IC in Australia

Image – Roller operator’s view of the Trimble tablet showing a CMV map of a recent compacted area.

As part of the NACOE project, the need to draft a technical specification was identified to use on the Queensland Department of Transport and Main Roads (TMR) projects to trial the IC technology. This led to the development of the first ever project-specific technical

Specification in Australia ‘PSTS116 Intelligent Compaction – Earthworks and Pavements’, which is intended for the use of the compaction of earthworks, unbound and stabilised pavement layers, but excludes asphalt layers and sprayed bituminous seals.

PSTS116 was initially developed to undertake a compaction audit using an IC roller on the Ipswich Motorway Upgrade: Rocklea to Darra – Stage 1 (R2D) project between March and October 2020. The IC roller was used to compact embankment fill, subgrade, plant mixed lightly bound material and unbound granular base material. The use of IC on this project has assisted TMR to evaluate the benefit of the technology and develop a strategy to implement IC into TMR’s standard specifications.

To support the implementation PSTS116 and the wider use of IC in Australia, NACOE has also funded updates to the international Veta software to allow it to be used in Australia and support GDA 2020. The Veta software was developed by the Transtec Group in 2012, and is used around the world to interpret and analyse Intelligent Compaction (IC), Paver-Mounted Thermal Profiles (PMTP), Dielectric Profile System (DPS), and future emerging Intelligent Construction Technologies (ICT).

Intelligent Compaction in Action

Image – The Logan City Council joint collaboration on the Logan Street Pavement Rehabilitation Project using IC technology.

NACOE was pleased to work with the Logan City Council on the Logan Street Pavement Rehabilitation Project, completed in late 2019, the first of its kind in Australia to capture data that allows the council to manage unstable ground in a more efficient way using (IC) technology.

The Logan City Council Street Pavement Rehabilitation Project won the Local Government Managers Australia Queensland (LGMAQ) Excellence Award 2020 in the Collaboration category.

The project utilised Intelligent Compaction (IC) technology, which allows the roller operator to gain real time feedback to test compaction quality and adjust as they go. This results in savings for ratepayers by identifying roads which are at early risk of failure before costly problems arise, while building better roads for Queenslanders.

The collaboration of multiple parties, which include Logan City Council; the National Asset Centre of Excellence (NACOE) – an initiative between the Department of Transport and Main Roads and ARRB – Australian Road Research Board; and QUT (Queensland University of Technology) has generated ideas in the road industry on how local governments can play a leading role in cutting edge road research and the development of innovative technologies.